engineering and simulation SERVICES to accelerate your development cycle and give you a competitive advantage.

DriveTwin can help you with the challenges you facE

Extensive experience gained over many drivetrain projects combined with access to next-generation CAE capabilities means that we can help you to make smart engineering decisions that will not only improve product quality and reliability, but also deliver development time and cost savings. Whether you are in the early stages of the development phase, investigating architectures, optimising components or virtually validating your design, we can help with a wide range of issues:

Engineering for Durability

DriveTwin has the engineering expertise to lead or work with you to ensure durability issues are identified and prevented before they become a problem.

Our expertise can help you size, select and engineer key drivetrain components to withstand their operating duty cycle. We can produce reports of component life rating to international standards, such as ISO, AGMA and DIN, to attest component durability.

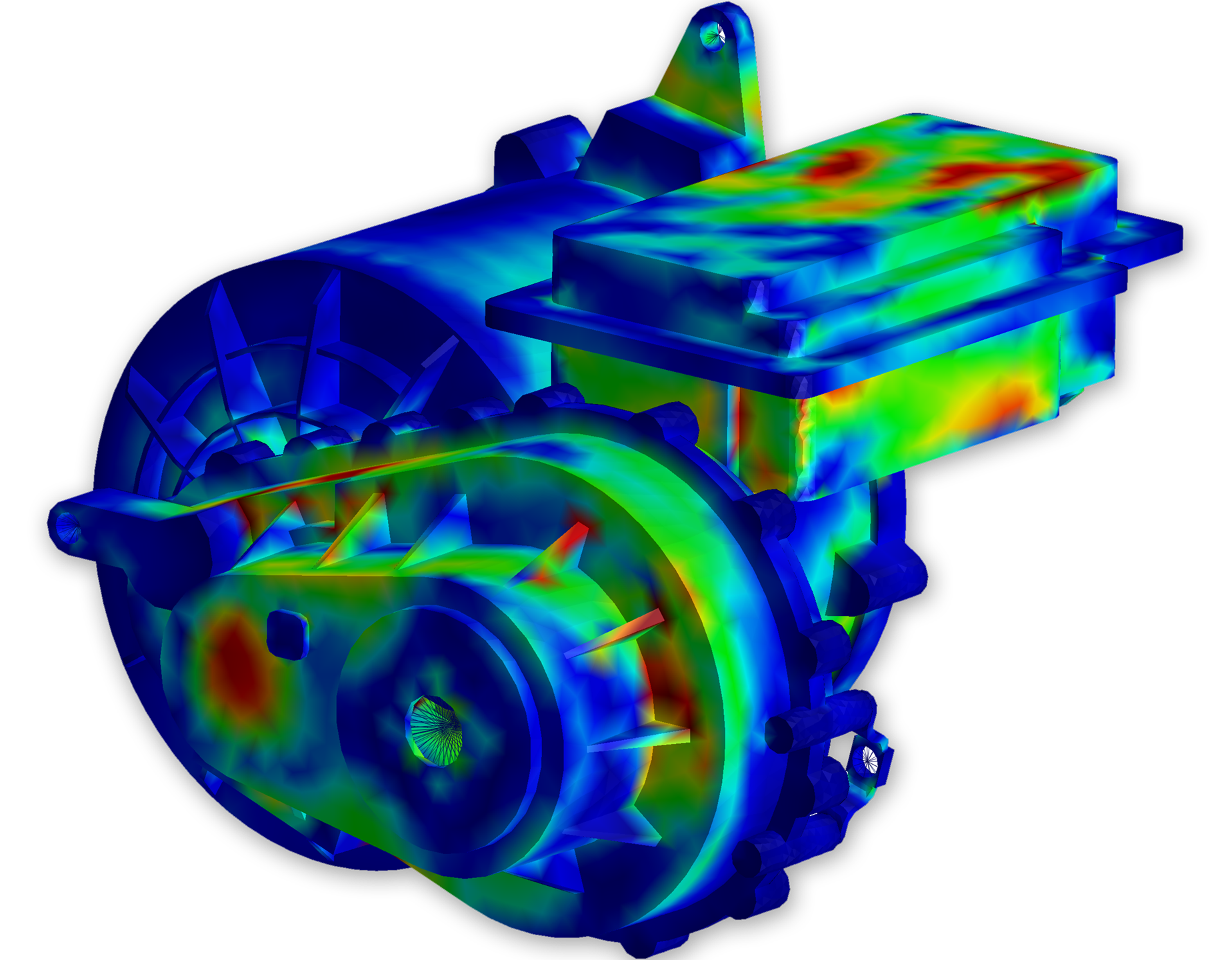

We can simulate any loading scenario to accurately assess component durability and identify areas of concern.

Product Optimisation & Virtual Validation

Product optimisation is often about balancing conflicting aspects, such as performance, weight, cost, efficiency and manufacturability. Our team is able to provide the insights required to help you balance trade-offs between these various aspects.

Hardware validation is traditionally costly and time consuming as multiple prototypes are required.

We can explore design changes and optimise the application in a virtual environment, so reducing testing time, with fewer prototypes and a faster time to market.

Meeting Noise & Vibration Targets

Designing and optimising for NVH requires a high degree of engineering expertise and next-generation simulation capabilities. For that reason we entrust the Romax platform with these tasks, as its high-fidelity simulation results have been validated through hardware testing on many NVH projects.

We can conduct vibration and acoustic optimisation on a synthetic environment to meet or exceed NVH targets and save you time and money. These are some of the issues the team at DriveTwin can help you with:

Reducing gear excitations.

Preventing resonance effects.

Acoustic radiation simulation.

Predicting natural frequencies and mode shapes.

Correlating vibration twins to test measurements.

Fine-tuning the design to improve NVH performance.

Maximising Efficiency

Efficiency must be considered from the early design stages. Design decisions made early in the conceptual phase can have an impact on the final system losses.

We can simulate power losses for all relevant drivetrain components and calculate overall drive cycle efficiencies, as well as efficiencies at specific loading conditions.

Robust Gear Engineering

Gears are integral to drivetrains and fundamental to our expertise. Our gear know-how is extensive and includes the design of gear tooth macro and micro geometry for robustness and manufacturability as well as high-speed gear design.

We can help with multiple issues relating to gears, such as durability, NVH (e.g. whine, rattling) and efficiency. We can help you to:

Define gear macro geometry with wider considerations (e.g. manufacturability, NVH, costs).

Define gear micro geometry to fine-tune the design (e.g. NVH, load sharing).

Devise optimum gear arrangements.

Maximise power density.

Bearing Issues

Combining our engineering know-how with the advanced bearing simulation capabilities of the Romax platform, we can help select, validate or troubleshoot bespoke and off-the-shelf bearings in any type of application. We can help with a wide range of bearing issues such as:

Bearing validation and life assessment (ie. ISO 281 / TS 16281).

Large bearing simulation (i.e. wind turbine, crane, hoist bearings).

Specification of operating clearances and fits.

Bearing and arrangement selection.

Preload optimisation.

OTHER challenges we can help you with:

Architecture generation

Technology advice

Rapid prototyping

AND MORE

The team at DriveTwin follow Agile methodologies

In addition to excelling in engineering and problem solving, we are trusted when it comes to project management and ensuring engineering rigour and value are delivered on time and to budget - every time.