The team at DriveTwin has experience with a vast array of drive system applications, from drive systems for EVs to precision drivetrains for robotics.

applications we can help with INCLUDE:

eDrives

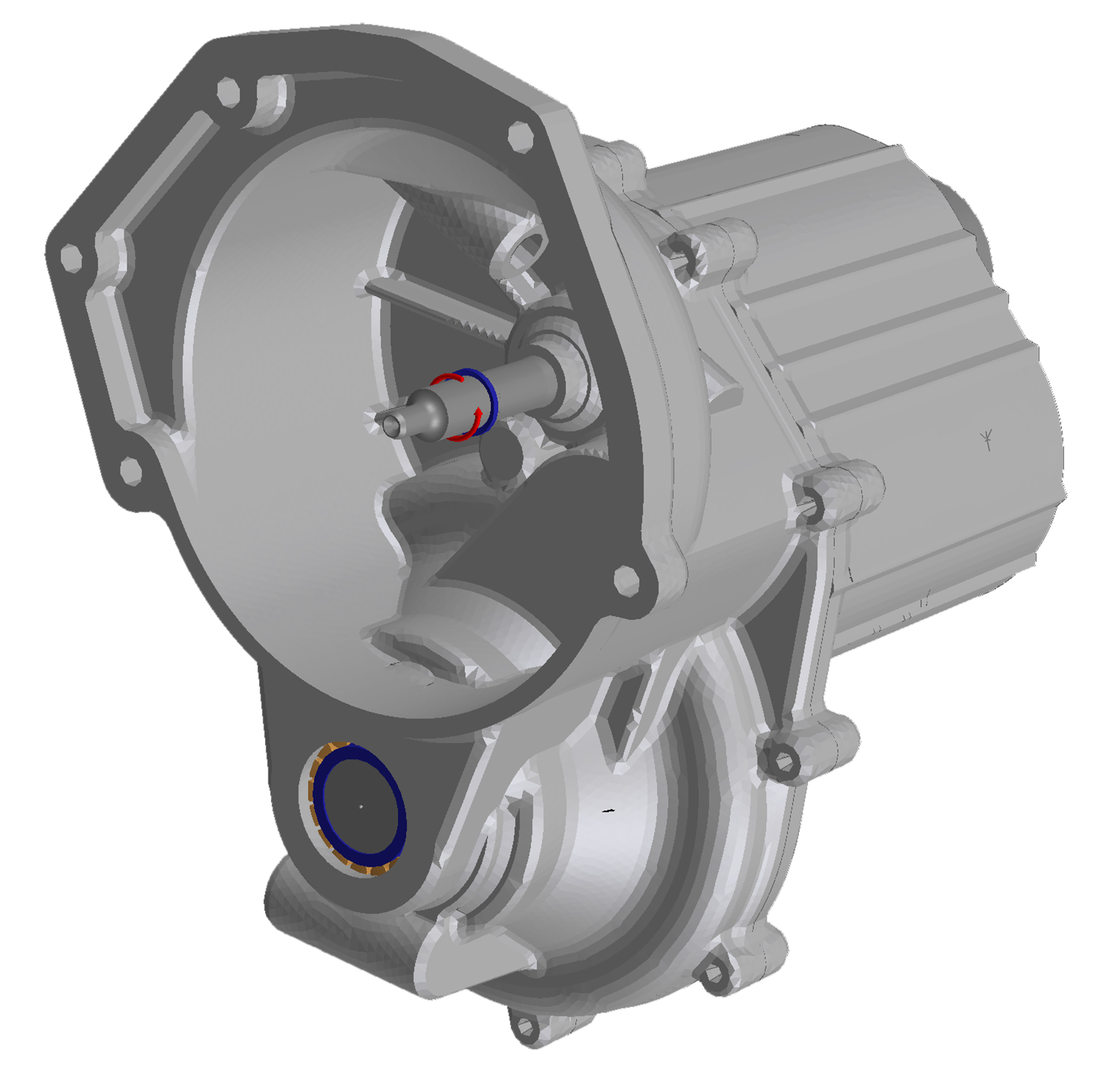

Drivetrains for EVs are core to our expertise: we have vast experience in this area and have delivered major simulation projects to OEMs and Tiers. EV drivetrains present new problems with respect to traditional drive systems:

Higher torques and speeds

Increased power density

Higher efficiency targets

Stricter NVH targets

Tighter packaging amongst other challenges.

DriveTwin can help you overcome these challenges. We combine engineering expertise gained on many successful EV projects with the simulation capabilities of Romax, the leading platform for the design, analysis, testing, and manufacture of next-generation eDrives.

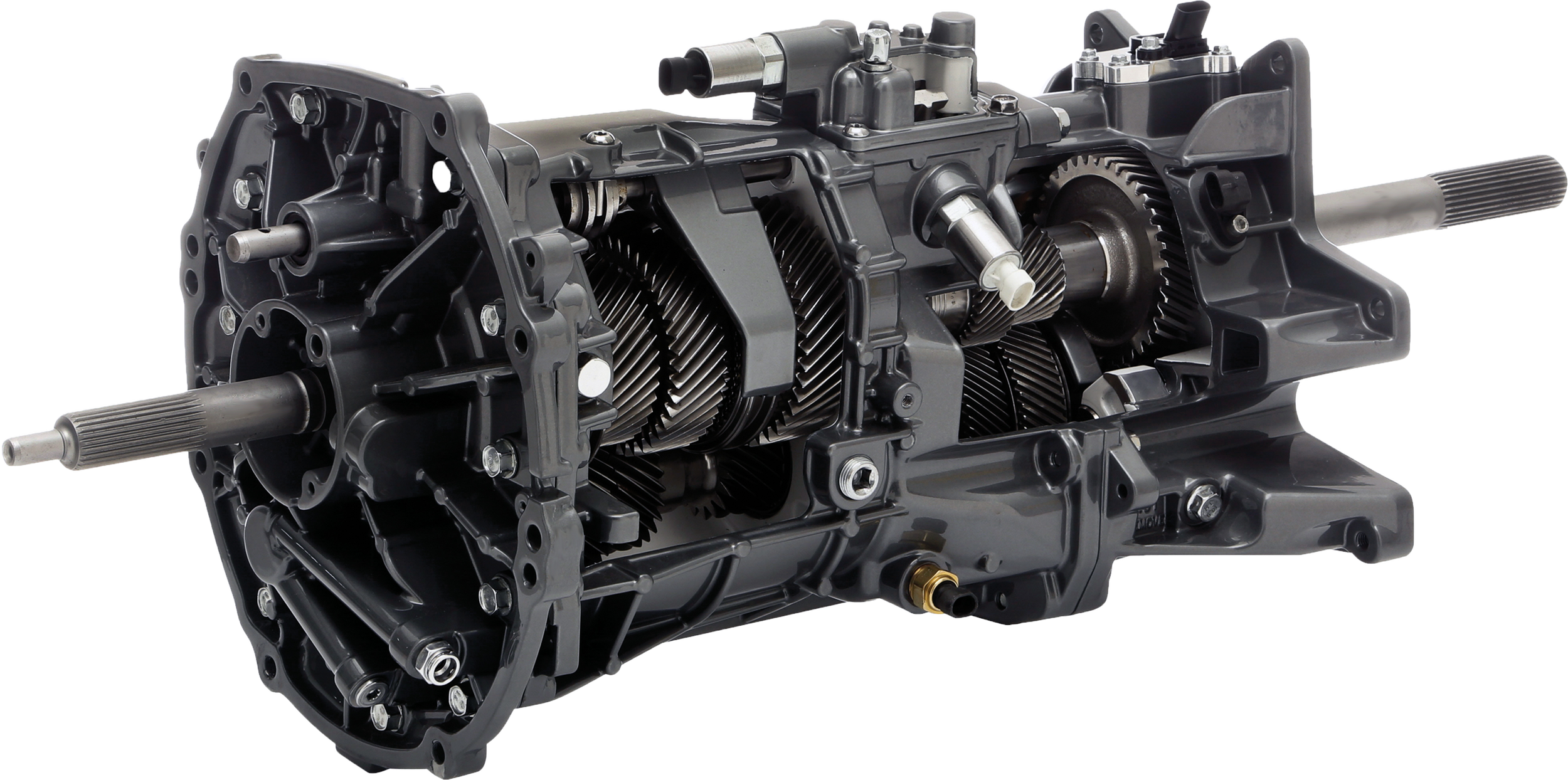

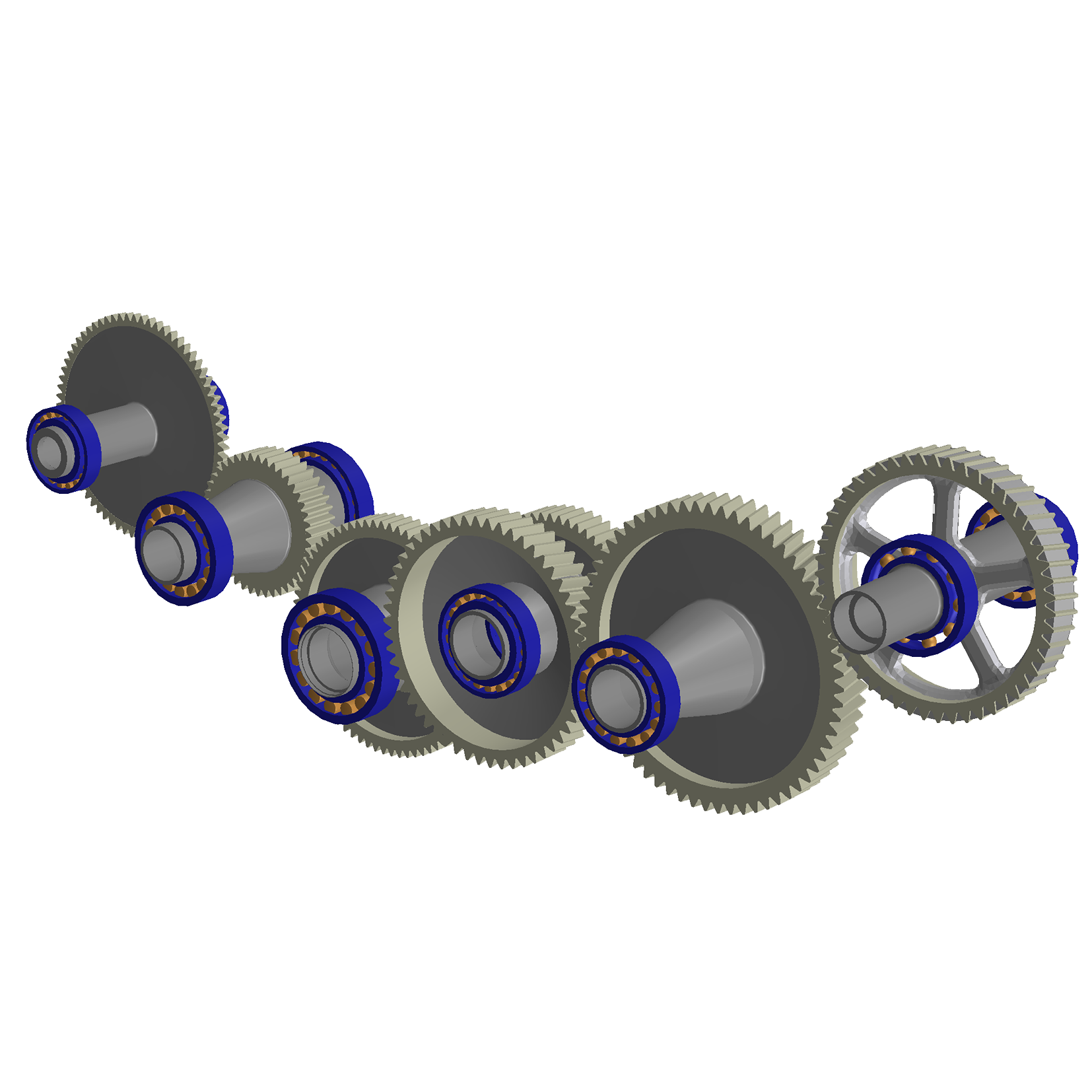

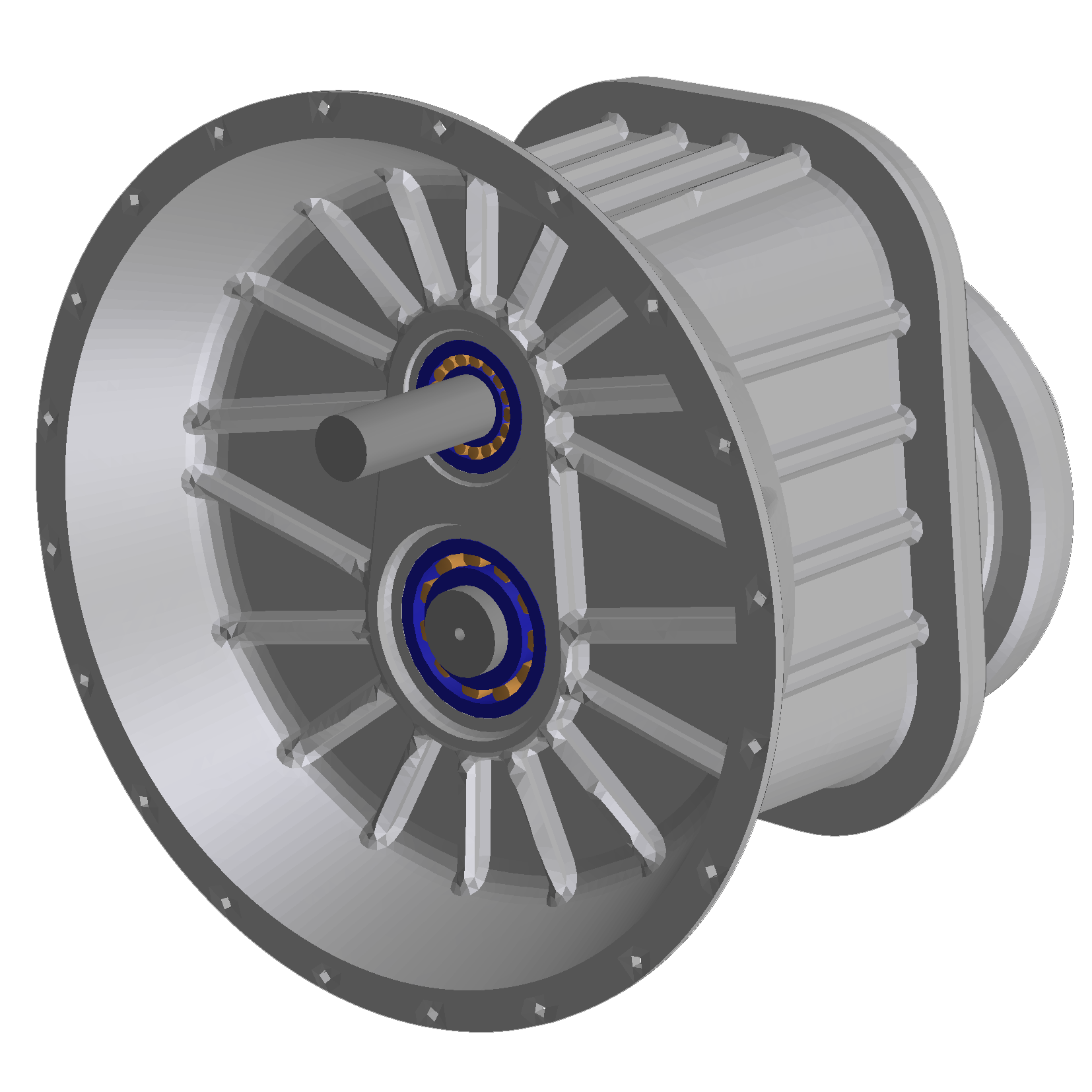

Multi-Speed Gearboxes, Transmissions & Differentials

You can also benefit from our deep experience in a wider range of automotive applications, including multi-speed gearboxes, transaxles, transmissions, transfers, PTOs, and differentials units.

Whatever your application - a high performance, lightweight, off highway or niche vehicle - DriveTwin’s team can help you troubleshoot durability, NVH, efficiency, and any other performance issues.

Multiphysics simulation capabilities enable us to develop high-fidelity models of the entire drive system including flexible structures, gears, bearings, splines, shafts, and other electro-mechanical components.

TREMEC TR-6070, MeMike200 (cc-by-sa/4.0)

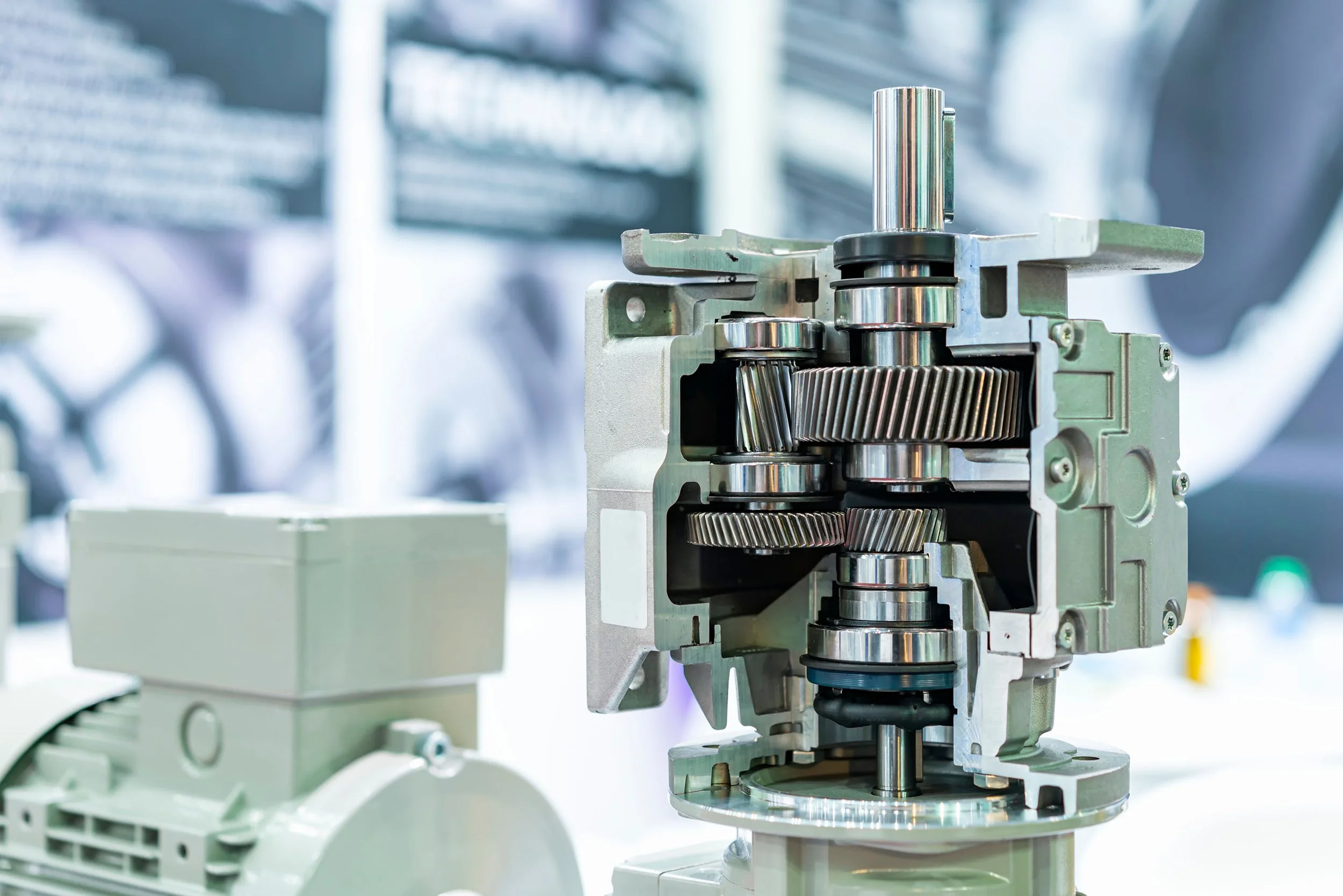

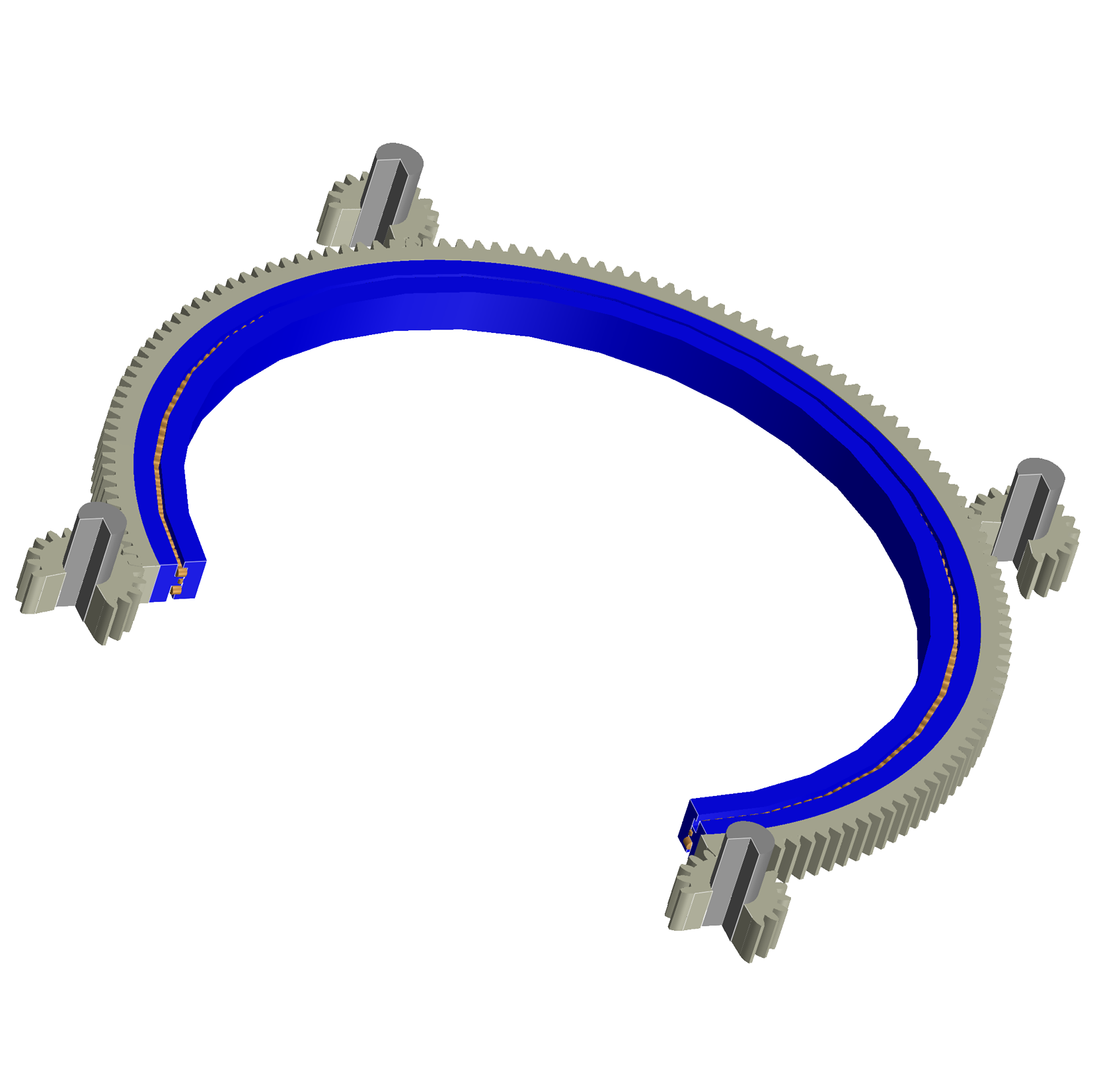

Reducer-Multiplier Gearboxes

The team at DriveTwin has extensive experience in non-automotive geared systems, including wind turbines, gearboxes, and industrial applications.

Our experience includes solving problems related to gearboxes with very large gear systems, epicyclic arrangements, power split stages, and large bearings such as slewing drives. We can help with performance assessment, validation, and the provision of engineering reports to support certification.

We can also assess the performance and troubleshoot issues related to outboard and inboard marine drives, and sterndrive propulsion systems.

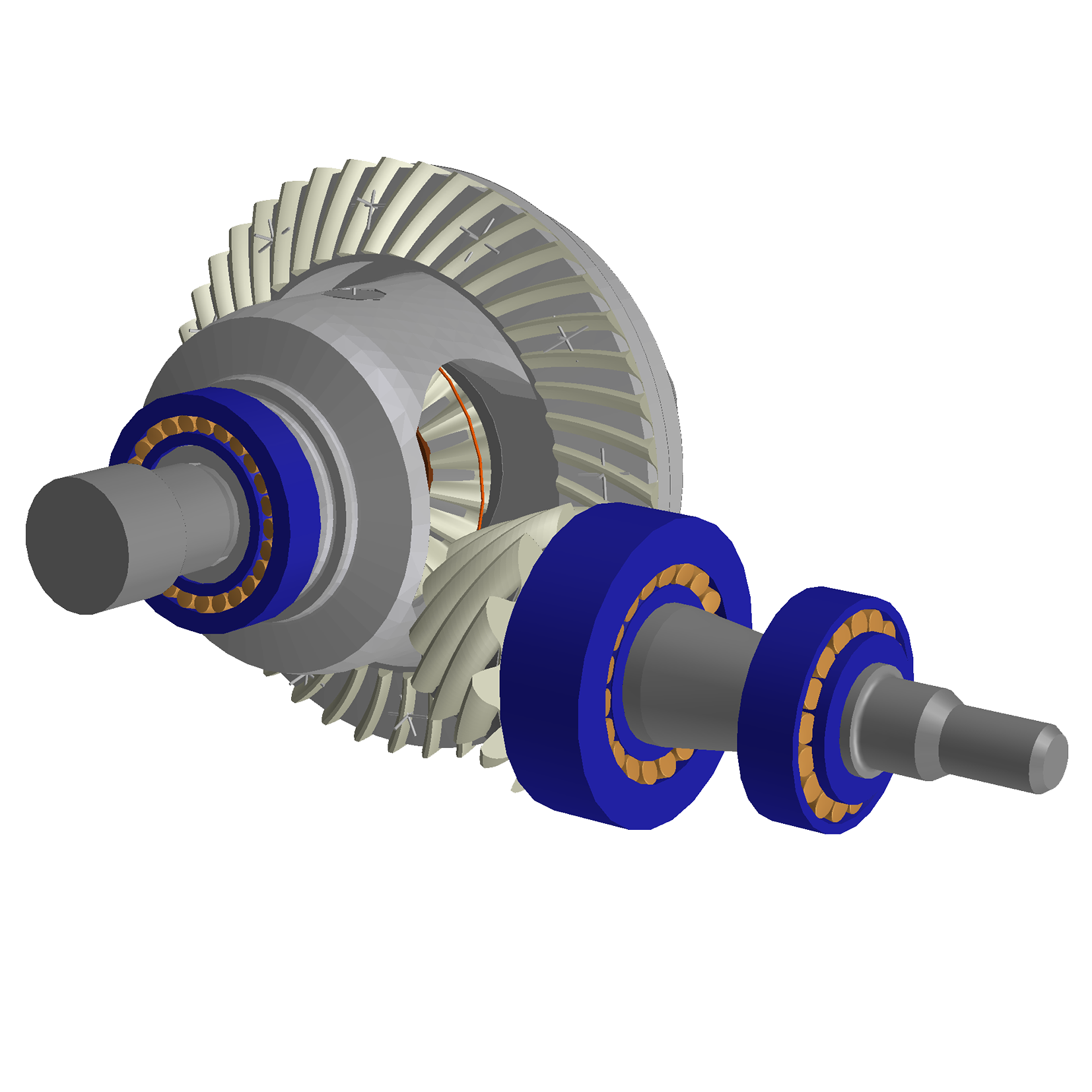

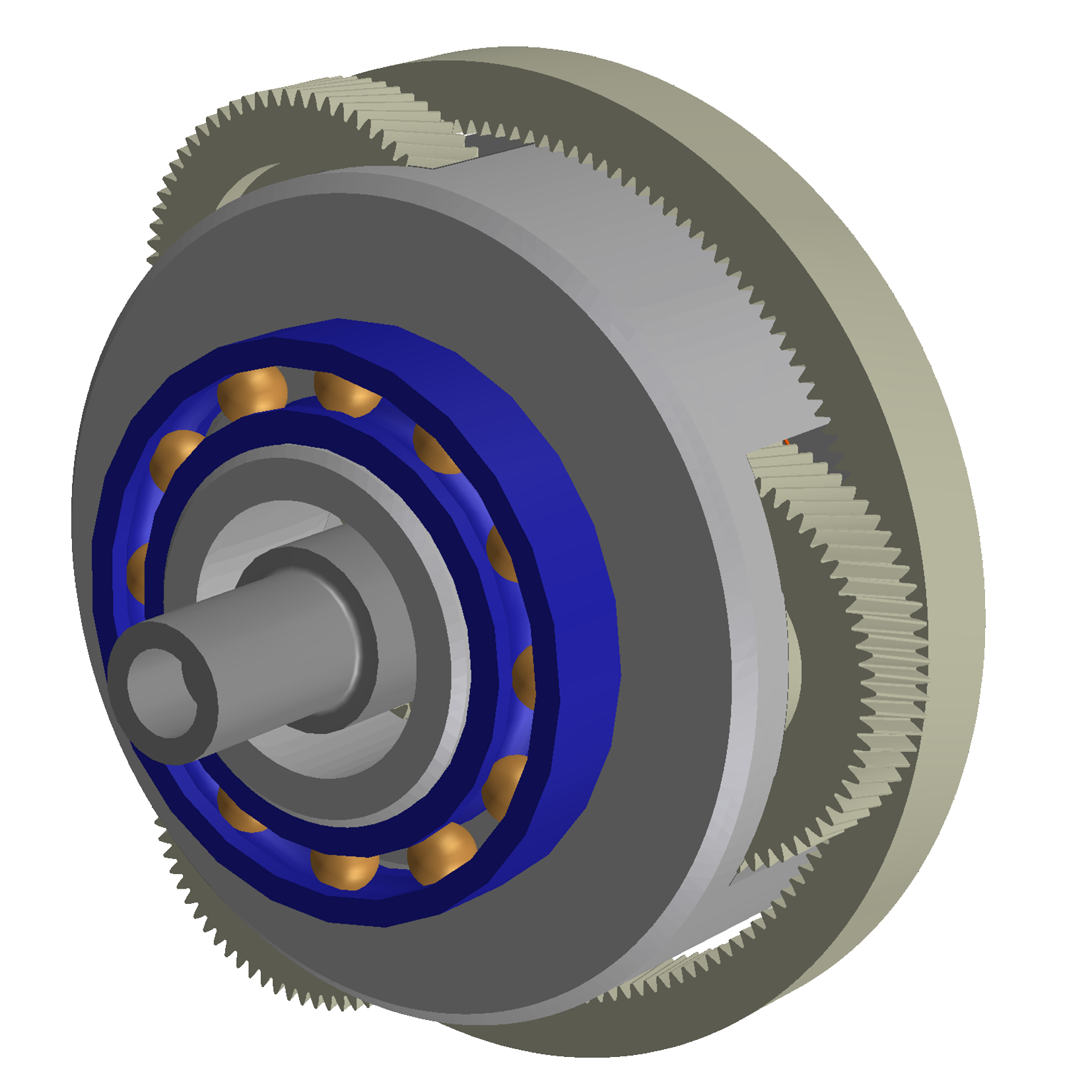

High-Precision Geartrains

We can help design, validate and optimise quiet high-precision gear drive systems to attain strict control of angular position and backlash, which is critical to the accuracy of robotic arms and grippers.

We can also engineer high-reduction planetary drive systems mated to low torque servo motors, such as those used in robotic surgery devices.

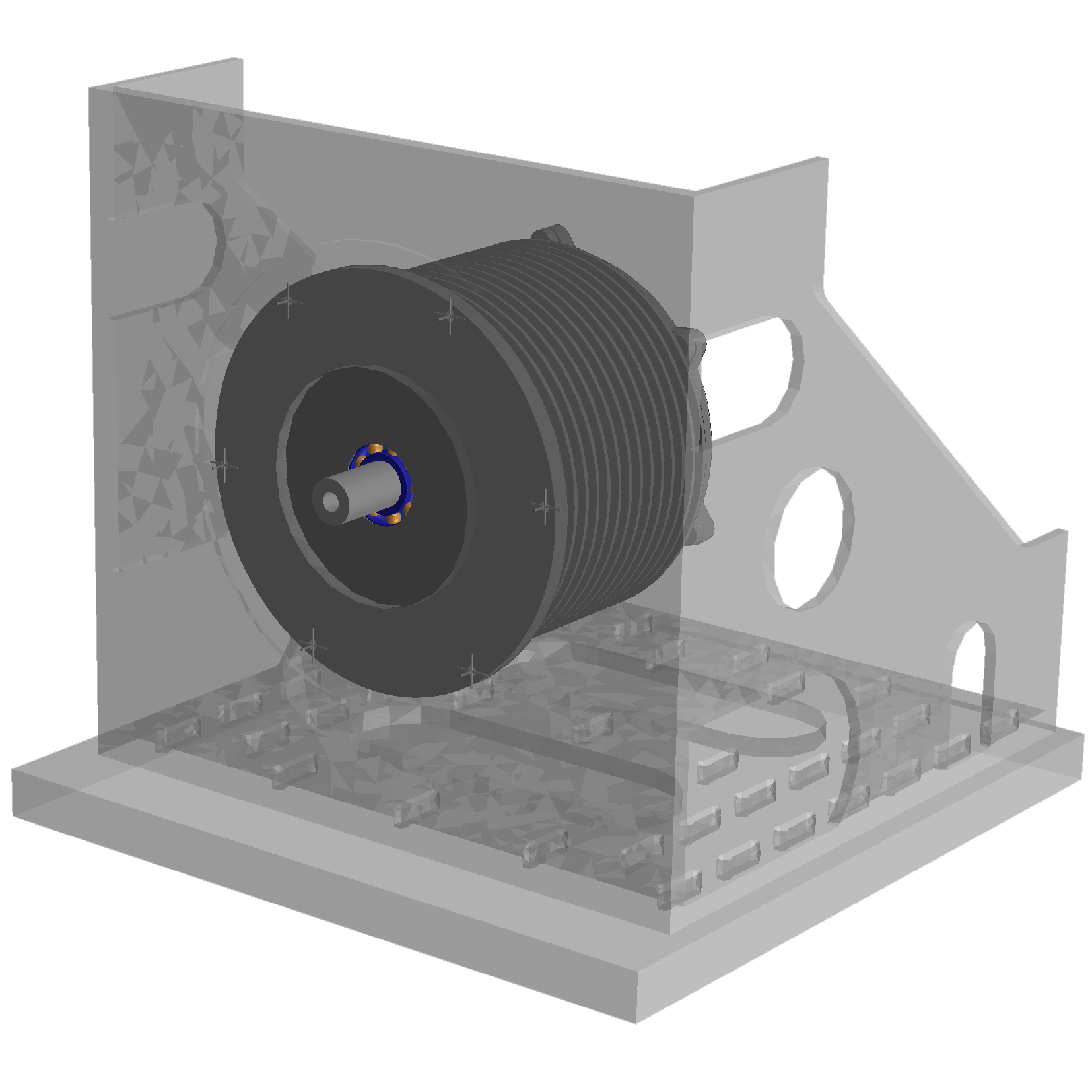

Geared Motor Units

We can help with the engineering and validation of all types of industrial gear units or bearing components for use on conveyors, hoists, cranes, and many other industrial applications.

We can capture the flexibility of surrounding structures, casings or frames to validate component durability and predict loads, stresses and deflections.

Leveraging expertise accrued over multiple projects to assist with your designs, gear engineering, component sizing, bearings and system optimisation.